Summer Sale - UP TO 50% OFFShop Now

Summer Sale - UP TO 50% OFFShop Now

Summer Sale - UP TO 50% OFFShop Now

Summer Sale - UP TO 50% OFFShop Now

2 to 5 Inches Taller Instantly

2 to 5 Inches Taller Instantly

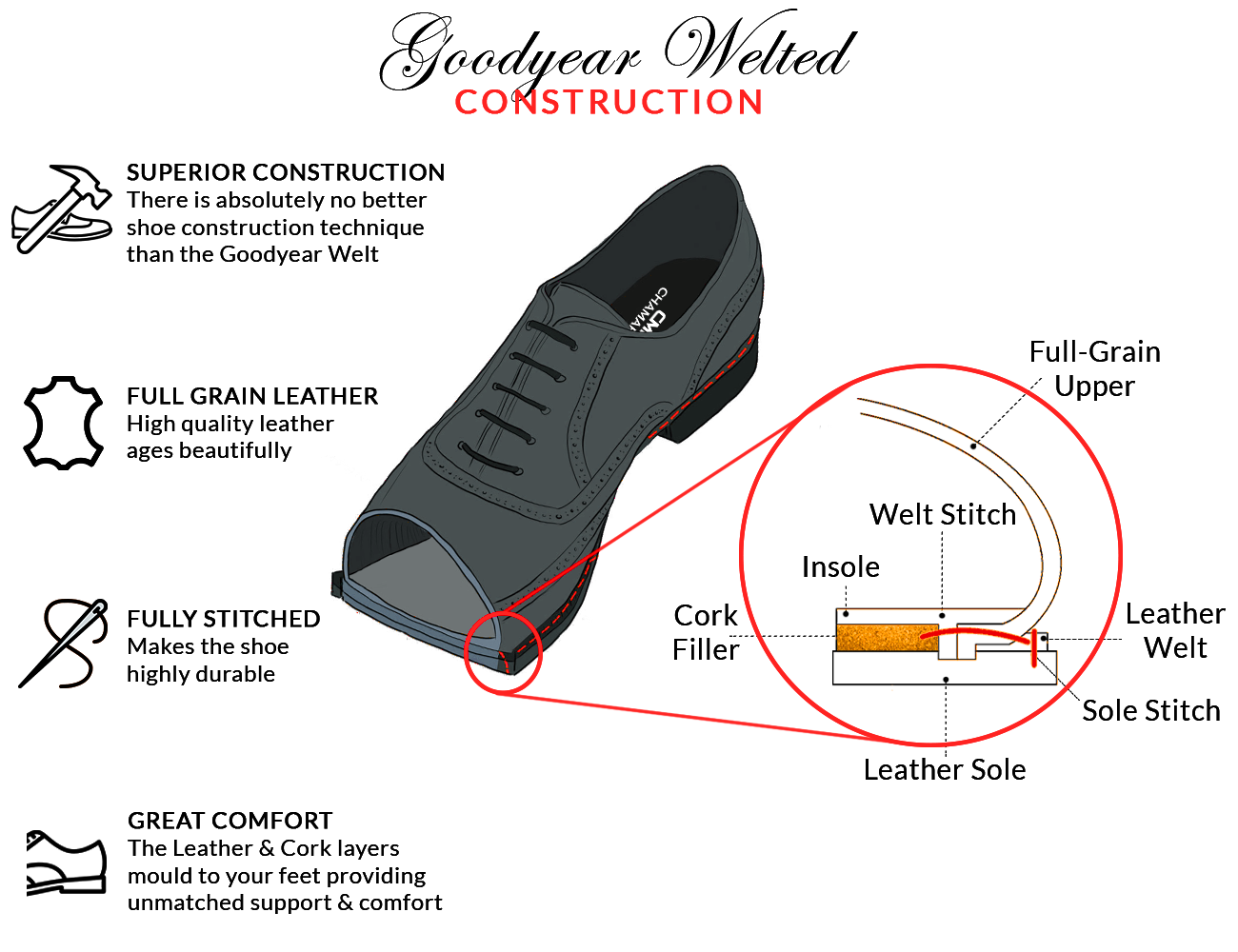

Goodyear Welted construction get its strength, durability and repair qualities by stitching the upper leather, lining leather and welt (a specially prepared piece of leather) to the ribbing that has already been bonded to the insole. The welt is then stitched to the leather or rubber sole. It is this final stitch, holding the sole in place, which we can cut through enabling complete removal of the sole without causing damaging the upper.

The Goodyear welt is the most laborious and durable method for the manufacturing of shoes. This can be done by hand or machine, however, both of these alternatives require highly specialized craftsmen. Following over 120 steps, it can take up to 15 days to manufacture a pair of shoes.

The leather will allow the foot to breather and the cork insole will add that extra comfort as it will mould to your step. In addition, the whole process is characterized by the overlaping construction elements that will offer an uncomparable resistance.

CMR Chamaripa shoemaker is well aware that the use of premium materials will yield a result of the highest quality. The previous cut leather will be sewn in the designed pattern in order to create the "Upper", the body of the shoe,( to which the welt is attached. )

The insole and welt will be sewn to the Upper. The welt is a strip of leather with an approximate 1,5cm width that will go around the whole edge of the Upper or only partly which will depend on it being a 360º or 270º welt. Once the welt has been placed, our craftsmen will proceed to cut off the excess leather.

The cork filling is next. This will allow the shoe to adapt your step after just a couple of days of use offering additional comfort and a personalized fitting and offer a greater stability to the step.

Last, the leather piece to act as the shoe sole will be attached.The shoe sole will be sewn to the welt and will be the base on which the heel will be set. At this stage, the sole has already been stitched twice. The first united the Upper with the welt and the second sewing connected the welt to the leather sole.